An important aspect of fleet management is using KPIs to track the overall performance of their fleet. These goals will make it easier for management and employees to comprehend what is expected of them on a monthly basis. Benchmarks are known to improve driver safety, lower costs, and increase FMCSA compliance.

WHY TRACK PERFORMANCE?

It is difficult to improve the overall productivity of your fleet if you don’t have any data to justify the changes in decision making. The only way to legitimately understand where improvements need to be made is to collect data on all aspects of your fleet and compare that data with previous months.

WHAT ARE KPI’s

Fleet managers use Key Performance Indicators (KPI) to help track and measure all aspects of their businesses. The benefits of using KPI’s with fleet management is the fact that you can measure exactly where improvements need to be made as well as where your fleet is having successes. These performance measures are objectives set in place for managers to help determine whether an aspect of their fleet is achieving its goal. These can be set for tracking fleet costs, utilization, and safety.

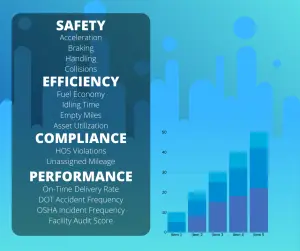

IMPORTANT ITEMS TO TRACK

There are multiple different items that businesses use to measure their fleet performance. Grouping these items into categories will help make the data results easier to manage. Safety, Efficiency, Compliance, and performance will be used in the following examples.

Safety can include tracking your fleet’s success rate for each individual safety measure put in place. For example, you will want to track speeding incidents, acceleration & braking incidents, corner handling, and collisions. Thanks to the breakthroughs in GPS tracking technology, setting up goals for this category is a lot easier than in the past and data can be updated in real time.

Efficiency will help track how well you are utilizing your fuel economy, idling time, empty miles, and assets. This information can give valuable insight of driver downtime and highlight what a fleet manager needs to address for drivers with low efficiency scores.

Compliance tracks how well your fleet conforms to the guidelines of FMCSA. For example, you could track an employee’s current available hours of service, HOS violations, and unassigned mileage.

Performance can help a fleet manager get a better understanding of on-time delivery rate, DOT accident frequency, OSHA accident frequency, and Maintenance facility audit scores.

Discovering new KPI’s and using them as benchmarks for you and your employees to focus will increase productivity, decrease costs, and improve overall fleet management efficiency, but understanding your current data before you set benchmarks is important.

CALCULATIONS FLEET MANAGERS NEED TO KNOW

When new fleet managers are hired, they need to do a heavy amount of calculations to determine where the company is positioned (especially if profits are struggling). They need to know all the costs per year and break them down into monthly calculations to figure out which changes (if any) need to be made. The most efficient method used today is calculating the total cost per mile.

To calculate your total cost per mile, you need to know the total fixed costs and total variable costs then divide those numbers by total miles driven. For example, if your monthly fixed costs (truck payments, insurance, permits, etc) equals $2,000 per month and your vehicle drives 8,000 miles in that month, then 2,000 / 8,000 = $0.25 per mile. Your fixed expenses are 25 cents per mile driven.

Depending on which expense you want to measure, this formula can be applied to any variable to show what it would cost per mile driven.

Another example, if you want to figure out what tire replacement is costing you per mile driven, then take the total amount spent that year for tire replacement per vehicle, divide by 12 to figure out average monthly cost and then use the equation below to get the results of tire cost per mile

INTERPRETTING RESULTS

Once you figure out how to calculate all the variables pertaining to your performance, then you will be able to move forward with comprehending exactly how much you need to charge to turn a profit. For example, if your calculations above equate to $1.00 per mile in expenses (variable and fixed) then you will have to charge more than $1.00 per mile to receive a profit. Breaking down all expenses will give fleet managers a better idea on what to charge for shipments. It is important to note that these calculations are simplified for easier understanding and when calculating variable costs you should understand that this number will fluctuate the more miles your vehicle is driven. Because of this, it is important to separate your variable cost calculations with your fixed cost calculations. After receiving your data for these different factors, you should get a better interpretation on which area the company or employees need to focus on for improvement. These will be the areas that you will set benchmarks for measuring your different KPI’s.

SETTING BENCHMARKS

Now that you have the data necessary to measure performance, it’s time to set benchmarks with different fleet KPI’s so your company and employees know what is expected of them. Whether this be safety compliance or cost reduction, all of it can be handled in similar ways.

The best way to increase safety compliance is to create a reward system with your employees. Set monthly goals for drivers to reach with data from your fleet management software (excessive breaking, speeding, accidents, etc). Fleet managers should print out monthly data results and rank the drivers in order. Posting these results in employee break rooms and/or through email will create a friendly competition within your organization that will result in everyone benefitting. If your employees are striving to be the safest driver in your company, then your overall safety compliance will drastically increase.

Some companies reward the top safety performers with added vacation time, gift cards, and cash prizes.

Setting goals for reducing cost is another fleet KPI that is useful. For example, if you find that your company is spending too much money in certain areas (whether it’s asset allocation or fuel economy), then you will know where you need to set benchmarks to combat the excessive costs.

EVALUATION AND CONTROL

The key performance indicators fleet managers set need to be reasonable and attainable, otherwise you are setting yourself up for failure. Meaning you are not creating a benchmark that is impossible to reach (“I want costs down by 100%!”). This will have an adverse effect on what you are trying to accomplish. If employees and managers feel the goals being created are too difficult, then they won’t bother attempting to reach them.

Fleet managers will also need to reassess how well their KPIs are doing and compare the data from month to month to see if any changes need to be made. If the results are showing growth towards the benchmarks (employees are being safer, costs in certain areas are going down) then you will know whether the goals you set in place are attainable or not. However, if you have been tracking this new data each month and none of your KPIs you set in place are being hit, then there is a good chance that you will need to re-evaluate and adjust.

IMPORTANT TIPS FOR FLEET MANAGERS

Attempting to lower costs that fluctuate from month to month (variable costs) are the best way to increase your profits as a fleet manager.

Fuel prices fluctuate from state to state based on taxes, so it is important to educate your drivers on which areas on their route will have the lowest base price. You are going to pay more taxes in Pennsylvania for fuel than you would in Missouri. This means you should try to adjust routes and fuel refill locations to increase your bottom line.

Build relationships with direct shippers so you can resist the need to use a broker. Deleting the middleman with your shipments will increase profits.

Technological advancement in ELD, GPS tracking, and Accounting can make your job a lot easier. Use these items to your advantage.

We have made a complete guide for Fleet Management available to everyone who needs it, check it out!

If you are setting a benchmark to lower your fixed costs and for some reason you just cant seem to hit that specific fleet KPI, then may I suggest lowering your preventive maintenance with a new customized fleet roadside assistance plan. Talk to one of our expert representatives at 1-844-6ENCORE to build a plan that works around what you need.

Comments are closed